Annual Savings

€119,559

Payback

12.0m

ROI

109%

CO₂ Saved

3.2t

Response Speed

432x

SunCalc

Turn numbers into better decisions

Quick results. Great savings.

Get instant insights into dispensing technology ROI. SunCalc delivers fast, accurate calculations so you can make smarter decisions, optimise costs, maximise returns – without the guesswork.

Customer Information

Please provide your contact details for the report

Side-by-Side Scenario Comparison

Configure your Current Scenario (how things are today) and your Future Scenario (with Sun Chemical dispensing technology) simultaneously. Both sets of sliders are visible side-by-side for easy comparison. The calculator shows the savings difference between the two scenarios.

Common Inputs (Apply to Both Scenarios)

Volume & Ink Costs

Total ink ordered annually (0 - 200,000 kg)

10,000 kg

Number of shifts the dispenser will operate (affects capacity)

Selected: 3 shifts (24 hours/day)

€0 - €30

€12/kg

€0 - €15

€8/kg

Spot Colour & Bases Information

0 - 30 bases

10 bases

0 - 100 colours

5 colours/day

0.5 - 20 kg

2.5 kg

30 sec - 10 min

4:30 min

Operations & Equipment

€0 - €100,000

€40k

€0 - €1,500

€550/hr

0 - 2,000km

500 km

Dispenser Active Time Calculation

Daily Dispenses

5

= 0.4 hrs/day active

Weekly Dispenses

25

= 1.9 hrs/week active

Annual Dispenses

1,300

= 98 hours/year active time

(3,250 kg total dispensed volume)

Equipment Investment

Manual adjustment (€0k - €500k)

€110k

Price Disclaimer: Indicative prices excluding options, shipping, installation, training and subject to site audit for pipework etc.

Cost Reduction Per kg

33.3%

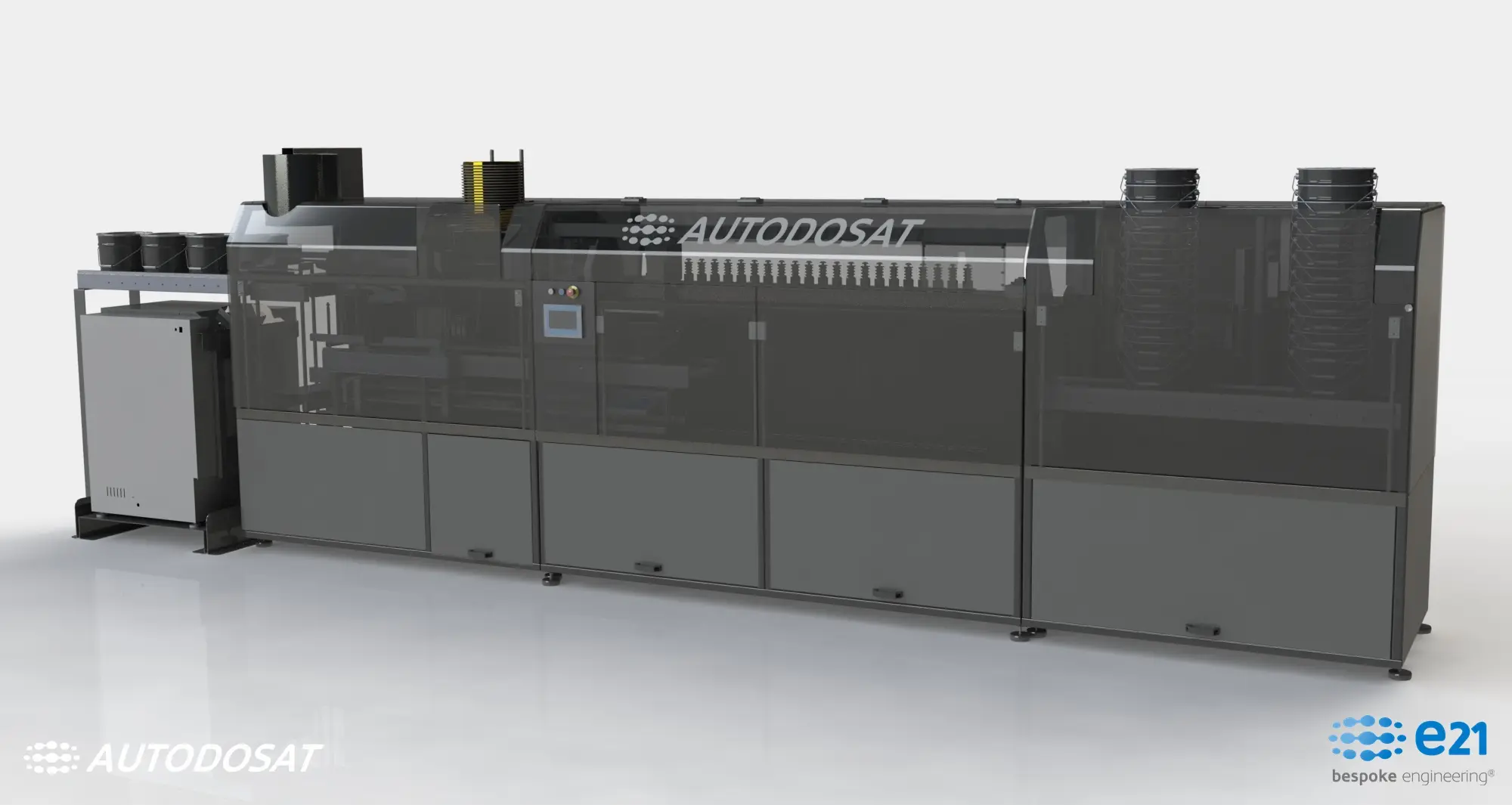

All Available Machines

Capacities shown for 3 shifts (24hrs/day operation)

Click any machine to override the recommendation and see custom ROI calculations

SunNetGlobal

0 - 15,000 kg/yr

€8k

28% utilized

SunHubOffset

3,000 - 30,000 kg/yr

€80k

14% utilized

SunHub2Offset

15,000 - 60,000 kg/yr

€179k

SunHub2Offset w/ MidiQ

30,000 - 120,000 kg/yr

€209k

SunAuto2.5Offset

30,000 - 210,000 kg/yr

€280k

SunAuto10Offset

30,000 - 390,000 kg/yr

€380k

SunHub3Offset

45,000 - 600,000 kg/yr

€250k

Complete Machine Comparison

Capacity shown for 3 shifts (24hrs/day)

| Machine | Capacity Range (kg/yr) | Investment | Status |

|---|---|---|---|

SunNetGlobal | 0 - 15,000 | €8k | Suitable |

SunHubOffset | 3,000 - 30,000 | €80k | Suitable |

SunHub2Offset | 15,000 - 60,000 | €179k | Too large |

SunHub2Offset w/ MidiQ | 30,000 - 120,000 | €209k | Too large |

SunAuto2.5Offset | 30,000 - 210,000 | €280k | Too large |

SunAuto10Offset | 30,000 - 390,000 | €380k | Too large |

SunHub3Offset | 45,000 - 600,000 | €250k | Too large |

* Indicative prices excluding options, shipping, installation, training and subject to site audit for pipework etc.

Scenario Comparison

Current Scenario (Today)

Over-Ordering Waste

Without tracking, printers typically over-order >50% more than needed

15%

= 1,500 kg waste/year

Ordered: 10,000 kg

Ink Mix Strategy

0% - 100%

100%

Bought-in

0%

Self-mixed

Staffing

0 - 10

1 FTE

0% - 100%

75%

0 - 15 hrs

2 hrs/wk

Logistics

€0 - €15,000

€5k

0 - 30,000 kg (Slow moving / Waste)

5,000 kg

0 - 5

2 /week

1 - 10 days

3 days

Future Scenario (with Sun Chemical)

Over-Ordering Waste

With Sun Chemical tracking, you can reduce over-ordering to 0-5%

2%

= 87 kg waste/year

Ordered: 8,587 kg

Ink Mix Strategy

0% - 100%

50%

Bought-in

50%

Self-mixed

Staffing

0 - 10

1 FTE

0% - 100%

25%

0 - 15 hrs

0 hrs/wk

Logistics

€0 - €15,000

€2k

0 - 30,000 kg

2,000 kg

0 - 5

1 /week

0 - 60 minutes (default: 10 min)

10 min

Inventory Reduction Transition Period

How long will it take to reduce inventory from current to future levels?

Inventory will be reduced gradually over 1 year, affecting your initial savings and payback period.

Your Savings & ROI Analysis

Your Annual Savings

That's €328 saved every single day

Scenario Comparison

Current Scenario

Total Annual Cost

€153,200

Future Scenario

Total Annual Cost

€33,641

Annual Savings

Current vs Future

€119,559

Payback Period

12.0

months

Annual ROI

109

%

Lead Time & Flexibility

Respond faster to customer demands with on-demand production

Lead Time Reduction

71.8

hours saved

Speed Improvement

432x

faster response

We shorten lead times from 3 days to just 10 minutes, making you 432x faster and enabling rapid response to market demands with on-demand production.

Dispenser Operational Metrics

Annual dispenser activity and throughput

Annual Dispenses

1,300

batches/year

Active Time

98

hours/year

Total Volume

3.3

tonnes dispensed

Based on 5 colours/day with an average batch size of 2.5 kgand 4:30 dispense time per batch. The dispenser operates 0.4 hours/day on average.

Environmental Impact

Reduce your carbon footprint & meet ESG goals

Annual CO₂ Reduction

3.2

tonnes CO₂

Equivalent To

152

trees planted annually

By eliminating 52 deliveries annually (52,000 km), local production significantly reduces logistics emissions and supports your scope 3 sustainability commitments.

Financial Savings Breakdown

5-Year Net Savings

After equipment investment

€485,096

No CAPEX budget? Consider our leasing option & flex your OPEX

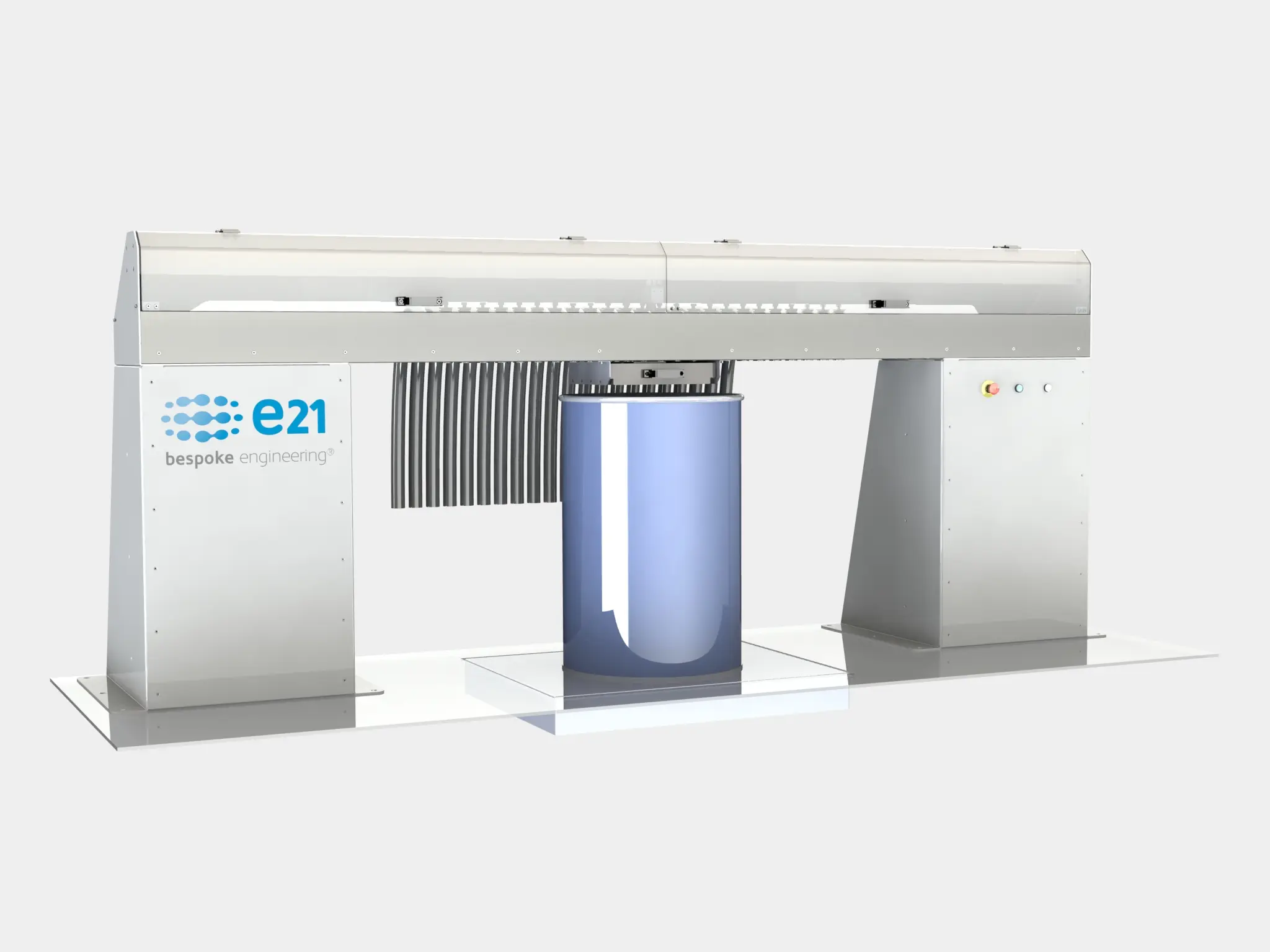

Our Machine Families

Advanced dispensing solutions for every production need

SunHub Family

Automated dosing for offset inks

Instant Production

Produce ink on-demand, eliminate waiting times, reduce inventory costs and audit ready traceability.

Consistent Quality

Every batch mixed to exact specifications with automated dispensing systems.

Lower Costs

Cut your ink costs dramatically while maintaining premium quality standards.

ESG Compliance

Reduce carbon emissions, support sustainability goals, and strengthen your ESG reporting.

Achieve More Compliance, Lower Cost, Less Complexity with Sun Chemical